| |

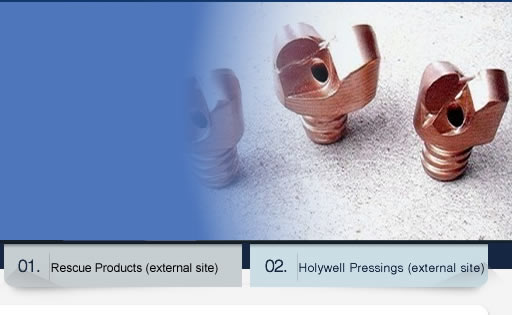

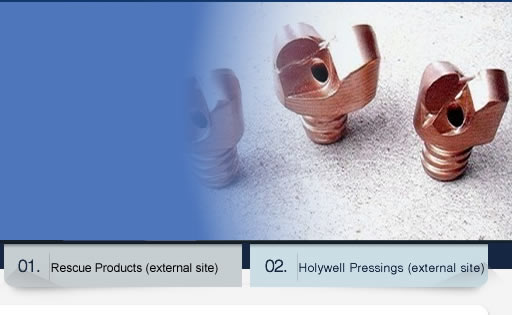

Ceramic Drillbits |

Replaces Percussion Drilling

Reduces Noise Levels

Reduces Drill Maintenance

Lower Drill Steel Costs

Improves Production

Replaces Percussion Drilling

Reduces Noise Levels

Reduces Drill Maintenance

Lower Drill Steel Costs

Improves Production

Brady's Ceramic Rotary drill bits are NEW and revolutionary for improving the

efficiency and mining costs associated with drilling.

Brady's Ceramic Rotary drill bits now out perform carbide percussion drill

bits in many HARD ROCK drilling applications such as roof drilling, tunnel

drilling and bench drilling. Formations of limestone, salt, shale, gypsum,

porphyry copper, lead-zinc, gold and platinum deposits are easily drilled with

Rotary drills and Brady's Ceramic drill bits. Brady's Ceramic drill bits are

capable of drilling very very hard, 36,000 psi compressive strength high

silica formations.

Brady's Ceramic Rotary drill bits reduce NOISE levels by 20 to 40 db's over

drilling with percussion drills and carbide bits.

Brady's Ceramic rotary drill bits can be used with 100% water or an Air

mist drilling system. Water volume may be reduced from a flow rate of 12-15

gpm to 1-3 quarts/min. in mines where high water volume is not desirable, by

using the Brady Air-Mist Drilling system and Ceramic drill bits.

Brady's Ceramic Rotary drill bits have proven to be very effective for Tunnel

and Bench drilling applications. Less drill maintainence, faster penetration

rates and longer bit life with Brady Ceramic drill bits, improves mine production.

Brady's Ceramic Rotary drill bits are cost effective, outlast carbide bits by

100 to 300 times, require no re-sharpening and reduce noise and respirable

dust levels substantially.

Brady's Ceramic Bits are available for Roof drilling, Tunnel drilling and Bench

drilling. For more information on "Drilling With Ceramic Drill Bits" contact

Holywell Engineering today.

| | |

|